Monitor & manage your shop floor with IoT enabled MyMachine system from wherever you are and maximize utilization and productivity.

StackEX MyMachin

Welcome to the world of Industry 4.0 technology machine monitoring. With the rise of Industry 4.0, monitoring machines has become more important than ever before. Thanks to advancements in technology, businesses can now monitor their machines in real-time and make data-driven decisions to optimize their production processes.

At its core, Industry 4.0 technology machine monitoring involves the use of sensors, data analytics, and automation to monitor and control the performance of machines. This technology can be used to monitor everything from small machines to entire production lines. By monitoring machines in real-time, businesses can identify potential issues before they turn into major problems, reducing downtime and increasing productivity.

One of the key benefits of Industry 4.0 technology machine monitoring is its ability to provide businesses with valuable insights into their production processes. By collecting and analyzing data from machines, businesses can gain a better understanding of how their machines are performing, identify areas for improvement, and make data-driven decisions to optimize their production processes. This can lead to increased efficiency, reduced costs, and improved quality control.

In addition to providing valuable insights, Industry 4.0 technology machine monitoring can also help businesses reduce downtime and improve maintenance. By monitoring machines in real-time, businesses can identify potential issues before they lead to downtime or breakdowns. This allows businesses to schedule maintenance proactively, reducing the likelihood of unexpected downtime and improving overall machine reliability..

At its best, Industry 4.0 technology machine monitoring is a powerful tool that can help businesses achieve significant improvements in productivity, efficiency, and quality control. Whether you are looking to optimize your production processes or reduce downtime, Industry 4.0 technology machine monitoring can help you achieve your goals. So why wait? Contact us today to learn more about how we can help you harness the power of Industry 4.0 technology machine monitoring

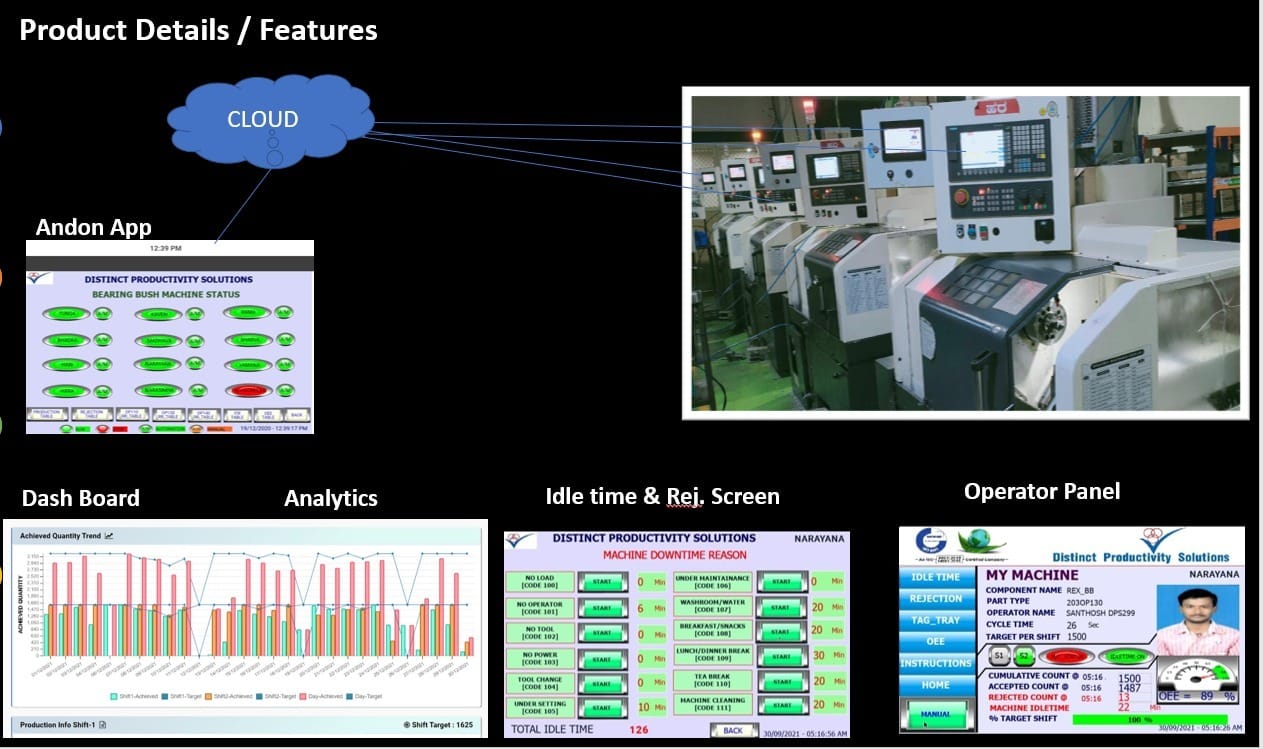

StackEX MyMachin Features;

- Each machine data can be seen / accessed by management real time.

- Oee data calculated, presented, stored for management on daily/monthly/ yearly basis.

- E-mail reports on daily production / rejection / idle time on periodic basis.

- Electronic andon for the entire shop floor

- Quick management actions as the analytics show top losses, top rejections, achievers , non-achievers in real time operators / middle management can be made more accountable.

How StackEX MyMachin Benefit To Industry

- Increased productivity and performance.

- Shop floor can be well managed & monitored remotely

- Multiple location management made easy

- Effortless audit readiness Traceability of production lot

- Proven 6 - 8 months ROI and Increased productivity

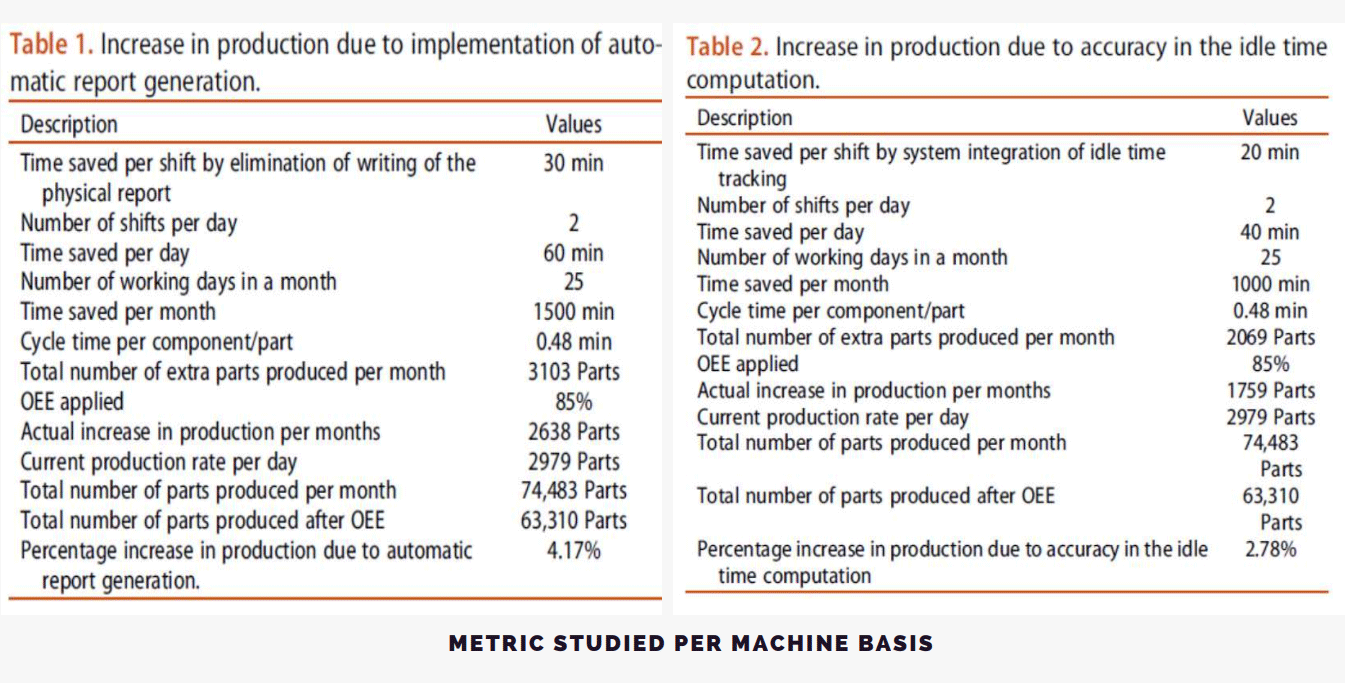

StackEX MyMachin Industry 4.0 technology machine monitoring solution offers a comprehensive range of reports for all levels of personnel within an organization, accessible on mobile phones, tablets, or laptops. These reports include:

- Hourly production reports, detailing individual cycle times, load/unload times, and other key metrics.

- OEE, A, P, Q, TEEP reports, providing valuable insights into machine efficiency and performance.

- Machine downtimes reports, identifying the causes of downtime and allowing businesses to take proactive measures to minimize it.

- Revenue loss reports, providing an accurate measure of the financial impact of downtimes and rejections.

- Rejections and rework reports, detailing measured inspection data to help improve product quality

- Consumables usage reports, providing insights into usage quantities and associated

- Operator-wise production and performance reports, helping businesses identify top-performing operators and areas for improvement.

- Maintenance incidences reports, detailing MTTA, MTTR, and MTBF to help optimize maintenance schedules and reduce downtime

- Long-term trend reports, identifying patterns and changes in key performance indicators over time.

- Multi-plant comparison reports, providing valuable insights for CEOs by comparing performance across multiple plants.

StackEX MyMachin Industry 4.0 technology machine monitoring solution, businesses can access these reports at any time and from any location, empowering them to make data-driven decisions and optimize their production processes for maximum efficiency and profitability.

CASE STUDY